30. Buy fully tested hardware

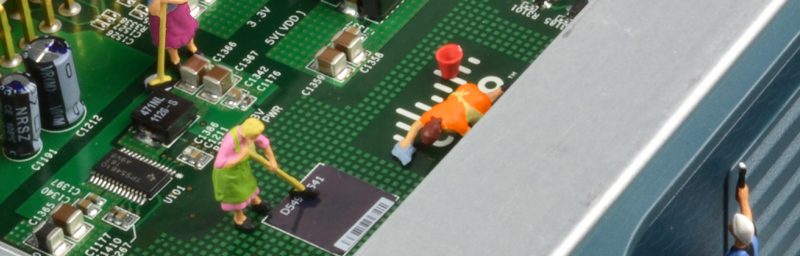

Testing pays dividends

Fascinating fact: as much as 6% of hardware equipment purchased new and delivered sealed fails to initialise on first start up. Largely this is down to shocks and vibration as the product passes through assorted warehouses on its journey from the manufacturer to your site.

Of course, if one of those 6% of devices happens to be critical to your network installation, this ceases to be a fascinating fact. It becomes instead a substantial pain in the neck, potentially costing you significant amounts. So, what can you do to avoid suffering at the hands of this particular statistic?

A basic principle

To answer that, let’s first review a basic principal. Just as your hot and cold water systems are fundamentally more important than the various appliances and fittings they serve (after all, the most expensive, all singing, all dancing shower is useless without a reliable water supply) so your network infrastructure is more important than the devices connected to it.

If you doubt this, consider for a moment the upshot of a key component of your network infrastructure arriving on its installation date and refusing to initialise. How many people will you have sitting around doing little more than honing their thumb-twiddling skills and charging you by the hour for the privilege? How many aspects of your business will be impacted? The total cost can be enormous.

Pre-installation testing

Addressing such risks comes down to pre-installation testing. However, simply having your supplier test equipment before shipping it to you, repacking it in its original packaging complete with test report, is only part of the story. After all, faults can develop in transit, even after such supplier testing.

However, this should catch all pre-existing hardware issues, as well as rooting out any potential compatibility problems – much better to know in advance than waste expensive engineering time because the pre-sales team failed to pick up on something when proposing devices and configurations.

Get involved

Being actively involved in deciding on the types of testing to employ pays dividends, as does making such decisions early on. Full traffic load testing, for example, is likely to cost more and take more time than basic loop-back testing, but if planned well and in advance, the time involved is likely to be significantly cheaper than the time involved in resolving problems resulting from faulty or incompatible components at installation time.

Undertaking such testing is also likely to be significantly less stressful and damaging to your reputation than managing problems on D-Day, with a couple of engineers hanging around idle and a testy customer tapping his watch and making sarcastic comments.

Knowledge, so the saying goes, is power. When it comes to advance knowledge of potential pitfalls it certainly is, so make sure your kit (new or refurbished) is tested thoroughly before despatch, make sure you are intimately involved in the testing process, and do it early on.